This is a step by step guide to assembling the Basic Boba Fett Display DIY kit. If you need assistance, email dustin.westaby@gmail.com

Versions

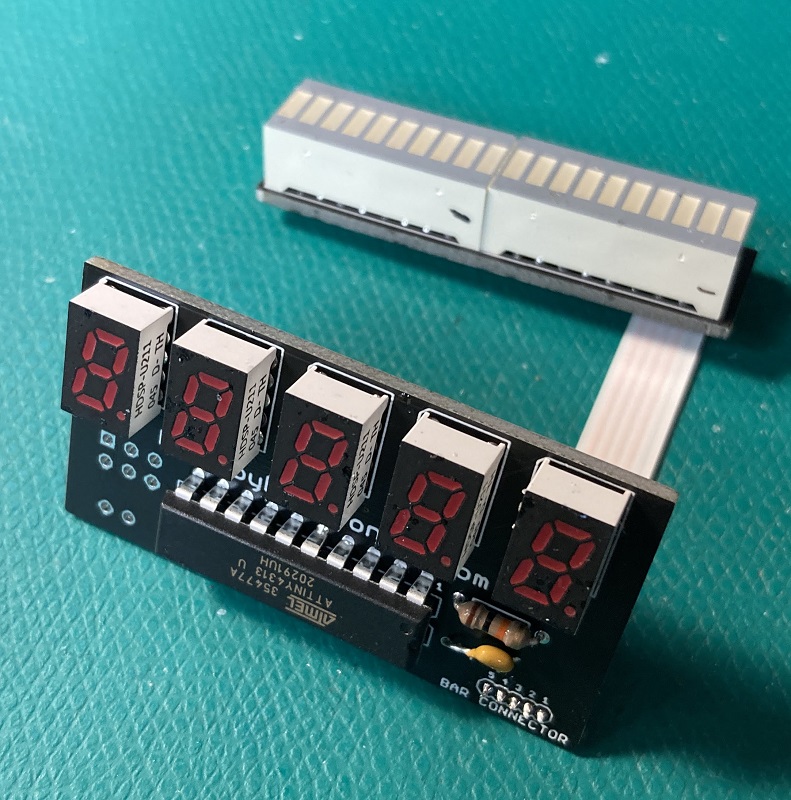

There are multiple versions of this kit. You are in the right spot if the your pcb is black and you have a 20 pin chip to install.

Video Tutorial

This kit has a video tutorial!

The latest version of the Basic Boba Fett Chest Display kit has a few differences from the video :

- No transistors

- Only one resistor

- Slim ribbon cable

- Single long 20 bar graph

Part List

Your kit contains two PCBs, a chip, and a ribbon cable. To complete your kit, you will also need the displays, resistor, capacitor, and battery clip.

- 1x AAx3 Switched Battery Pack (12BH331/CS-GR)

- 1x LED Bargraph Red (DC20/20EWA)

- 5x LED 7 Segment Display Red 0.3″ CA (HDSP-U211)

- 1x Spare Resistor, 1k ohm

- 1x 1uF 10V Ceramic Capacitor (K105Z20Y5VE5TH5)

- 1x Resistor 10kohm 1/4W (CF1/4C103J)

Click here to one click order the above parts from Mouser.

Click here for some alternate part numbers if anything is out of stock.

Pre-Assembly

Before we assemble, take a moment to familiarize yourself with the parts.

DO NOT SKIP THIS STEP. The displays can be inserted into the pcb upside down, but will only work when installed the right way round.

The above drawing demonstrates how to test the bargraph polarity. The bargraph will light up one way but not the other.

Insert batteries into your battery clip, flip the power switch on, and hold the wires with the spare 1k ohm resistor (brown black red colors). Touch the bargraph display pins to find which side lights up.

When the bargraph lights up, you have the wires in the correct position. Use a marker to write + (positive) on the side with the red wire / resistor, and write – (negative) on the side with the black wire.

Repeat for the second bargraph display.

Assembly

It is important that you use electrical solder. You need solder with flux inside. The flux removes oxidation from the metal, helps the solder flow, and transfers more heat from the solder iron. Your joints will be stronger and faster.

TIP: If this is your first time soldering, save some time and buy a $20 kit (link) that comes with the solder iron, solder, wire stripper, and cutter. In addition, this educational video is quite old, but is the BEST explanation of how to solder and why we use flux solder for electronics. Basic Soldering Lesson 1 – “Solder & Flux”

Character Displays

Orientation matters. Your character displays have a small period dot on the front. Line it up with the photo below. The displays will not work upside down.

You can install the displays and solder one at a time, or all at once.

Once you solder the pins, use a flush cutter to remove the extra pin length.

Chip / Resistors / Capacitor

Orientation matters. Examine your 20 pin chip and you will see a notch on one end. This notch aligns with the drawing on the circuit board. Install the chip so the notch matches the drawing.

Refer to the photos below. Once your chip looks correct, solder the chip pins on the backside.

Install the resistor and capacitor. Solder in place and trim the excess leads with a flush cutter.

The part list included two resistors. Either will work here, but you will have better battery life if you use the brown black orange colored resistor (10k ohm).

Bargraphs

You did the pre-assembly step and marked your bargraphs with +/- already right? Now is the time to look at the bargraph PCB. On either end you will see + / – written. This MUST match up with your display’s +/- markings.

Install the bargraph on the side with the bargraph drawing.

Ribbon Cable

Caution: The ribbon cable can be brittle, be careful to only bend once.

Orient the two display circuits as shown. Insert the ribbon cable, but do not bend yet. Solder the pins to the circuit.

After soldering, use a flush cutters to trim the extra pin length.

Check for any bridged connections, where there is too much solder and two pins are connected. Use your solder iron to re-heat and quickly pull away to clear out any extra solder.

Repeat for the other side.

You can bend the ribbon cables now, or wait until after power up testing. Recommend hot glue on each end of the ribbon cable (see below).

Power

The part list includes an easy to use switched 3xAA battery box. The 3xAA battery box has two wires, red and black.

- Red is + (positive)

- Black is – (negative)

Wire the battery wires to the + / – connectors at the bottom of the circuit.

Hot Glue

Once everything looks good and your circuit powers up ok, you can take extra steps to add strain relief to the wires and ribbon cable.

Add hot glue to either end of the ribbon cable. Above and below. This allows the cable to flex and bend, but not bend or stress the solder joint.

Mounting in your Costume

The two circuits are separate to fit a variety of costume designs. You can expand or narrow the distance as needed.

For very short lengths, you can also fold the ribbon cable in a zig zag to make it extra short.

Use hot glue or epoxy to affix to your armor. The battery pack can be heavy, make a pocket shelf or use heavy duty velcro.

To help with alignment and block light leaks, you can use craft foam. Cut to match the circuit size, then glue the foam and circuit into your armor.

Troubleshooting

Parts out of stock? Backordered?

This happens from time to time. You will need a replacement part. Go ahead and add all the mouser.com project parts to your cart and delete the backordered one. Then add one of the subs below.

Be careful in picking your own substitute parts. The parts list below are pre-approved as ok.

There are two colors of red to pick from. Bright Red (brighter) and High Efficiency Red (dimmer). In my opinion the high efficiency red photographs better, but the bright red would be better suited for outdoor cosplay. Make sure to pick the same color red for both the bargraph and character display.

| Part | Quantity | Mouser Substitutes | Definitions |

| Character Display | 5 | HDSP-U101 HDSP-U111 HDSP-U201 HDSP-U211 | U1xx = Bright Red U2xx = High Efficiency Red Ux0x = Gray Background Ux1x = Black Background |

| Bargraph Display | 1 or 2 | DC10SRWA DC10EWA DC20/20SRWA DC20/20EWA | DC10 = 10 Bars DC20 = 20 Bars SRWA = Bright Red EWA = High Efficiency Red |

| Resistor 1k | 1 | TBD | |

| Resistor 10k | 1 | CF1/4C103J CFS1/4CT26A103J CF1/4CT52R103J CFS1/4CT52R103G CFS1/4CVTR103J | 1/4 = 1/4 Watt 103 = 10k ohms |

| Capacitor | 1 | TBD | |

| Switched AA Battery Clip | 1 | 12BH331/CS-GR 12PH331-IP-GR 12BH431/CS-GR PW-3AA | IP = Water Resistant 331 = AA 431 = AAA |

Dark segment on one of the character displays?

Display not light up right?

Check your solder work for places with not enough solder or too much solder.

Touch up your solder joints. Remelt each one, add solder to spots that need more. Pull away solder from spots that have too much solder. Adjacent joints should not be touching!

Review this soldering touch up video: https://www.youtube.com/watch?v=OaBRak0HnQs&ab_channel=Androkavo

Bargraph display look scrambled?

Your bargraphs are installed backwards. Use a hot air rework station to remove the displays and flip around. Here is a comparison of the ESB animation sequence on a backwards installed bargraph.

Your bargraph ribbon cable is shorted (too much solder). Use your smartphone’s magnifier app to look for any solder between pins on either end of the ribbon cable. If you find any, re-heat and pull the solder away with your iron, wiping off the iron each time, until the excess solder is gone.

No lights at all?

You may also notice your chip or batteries are overheating. Switch off right away! The chip can burn out and you are draining your batteries.

Check your power wires. Typically, the red wire is + (positive) and the black wire is – (negative).

Check the switch on your battery pack. Make sure it is ON.

Use a fresh set of batteries. The display will be very dim with less than ~3V.

Touch up your solder joints. Remelt each one, add solder to spots that need more. Pull away solder from spots that have too much solder. Adjacent joints should not be touching!

Review this soldering touch up video: https://www.youtube.com/watch?v=OaBRak0HnQs&ab_channel=Androkavo

Broken ribbon cable?

Doh! The ribbon is flexible, the joints are not.

- Option 1: You can carefully add solder to each of the broken joints. Mending the cable back on.

- Option 2: Use your own wire instead of the ribbon.

- Option 3: You can purchase a replacement ribbon. Email: dustin.westaby@gmail.com

Once fixed, add hot glue to prevent the joints themselves from flexing.